Elise Biopharma is a leading US-based CDMO dedicated to advancing microbial fermentation technologies specifically tailored for recombinant microbial proteins. Our comprehensive services encompass strain engineering, detailed process development, analytical services, and full-scale cGMP production for a diverse array of applications, including advanced therapeutics, vaccines, and critical biologics.

Specialized Services & Capabilities

We emphasize personalized attention and flexibility, particularly prioritizing small- to mid-scale programs that are typically underserved by larger CDMOs. Our dedicated 4,000 sq. ft. microbial process development and manufacturing cleanroom facility is designed to meet and exceed the most stringent industry standards and your unique fermentation requirements.

Comprehensive CMC Development

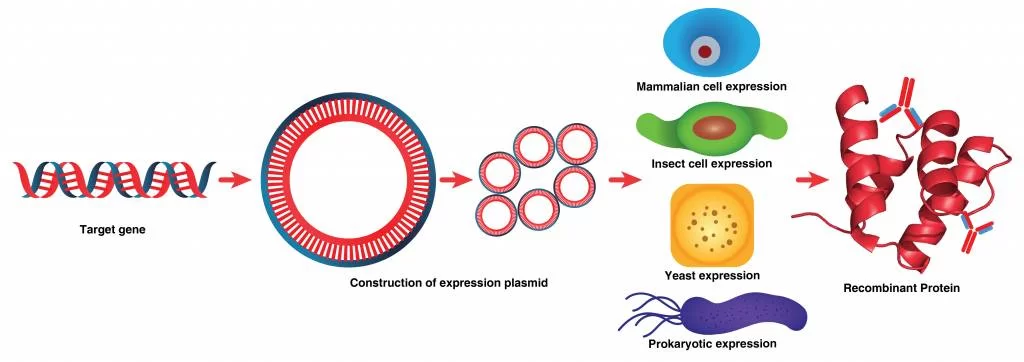

Our integrated Chemistry, Manufacturing, and Controls (CMC) services ensure a seamless transition from initial strain development through clinical phases and commercial-scale production:

- Strain Development & Optimization: Employing advanced synthetic biology, genome editing tools (such as CRISPR-Cas systems), and microbial genetic technologies to engineer highly productive microbial strains.

- Process Development: Tailored optimization of fermentation conditions, media formulations, and downstream recovery methods to maximize yields and ensure purity.

- Analytical Development: Robust quality control analytics, including HPLC, mass spectrometry, SDS-PAGE, Western blotting, and ELISA methodologies, ensuring accurate product characterization and method validation.

cGMP Manufacturing

We operate state-of-the-art facilities compliant with global GMP standards:

- Fermentation Capacity: Scalable fermenters ranging from bench-scale (5 L to 50 L) to industrial production scales up to 2,000 L.

- Robotic Aseptic Filling: High-precision robotic systems for drug product (DP) manufacturing, ensuring sterile filling and packaging of final products.

- Cleanroom Suites: Our segregated Grade C cleanroom suites facilitate upstream fermentation and comprehensive downstream processing, including cell lysis, product extraction, protein purification, and product concentration.

Specialized Applications and Supported Products

We produce a wide range of recombinant microbial proteins catering to diverse industry requirements:

Biotherapeutics

- Enzymes: Therapeutic enzymes for enzyme replacement therapies, diagnostics, and biocatalysts.

- Cytokines: Growth factors, interleukins, and interferons critical in immunotherapy and regenerative medicine.

- Antibody Fragments: Single-chain variable fragments (scFvs), Fab fragments, and other engineered antibody variants for targeted therapeutics.

Advanced Vaccine Components

- Antigens: Recombinant protein antigens optimized for enhanced immune response.

- Virus-Like Particles (VLPs): Highly immunogenic non-infectious particles for safe and effective vaccines.

- Adjuvants: Protein-based adjuvants that enhance vaccine efficacy.

Research Reagents and Critical Raw Materials

- Recombinant Proteins for Diagnostics: Antigens and control proteins for diagnostics and assay development.

- Protein Standards: Reference proteins for analytical and quality control purposes.

Bioconjugate Intermediates

- Drug Conjugation: Recombinant proteins designed for conjugation to small molecule drugs, forming antibody-drug conjugates (ADCs).

- Labeling Reagents: Proteins engineered for fluorescent, radioactive, or enzymatic labeling used in research and diagnostics.

Facility and Infrastructure

Elise Biopharma’s microbial facility features advanced modular cleanrooms with dedicated air handling units delivering tightly controlled, HEPA-filtered environments from EU Grade D to Grade A standards. Equipment flexibility and adaptability are prioritized, allowing rapid reconfiguration for diverse microbial fermentation projects:

- Modular cleanroom designs enabling rapid process setup and changeovers.

- Integrated systems for microbial fermentation, high-pressure homogenization for cell lysis, tangential flow filtration, chromatography-based purification systems, and ultrafiltration/diafiltration.

- Comprehensive infrastructure, including electrical and process gas supply networks to support advanced fermentation bioprocesses.

- All equipment and consumables sourced from reliable American manufacturers, with extensive on-site maintenance and technical support capabilities.

Advanced Technologies and Innovations

We continuously integrate cutting-edge technologies and innovative practices to enhance microbial fermentation efficiency and product quality:

- Real-Time Monitoring: Advanced process analytical technologies (PAT) providing real-time monitoring of fermentation parameters (pH, dissolved oxygen, optical density, metabolite analysis).

- Automation: Integrated bioprocess automation systems ensure precise control, reproducibility, and scalability of fermentation processes.

- Data-Driven Optimization: Leveraging AI-driven modeling and machine learning to predict optimal fermentation conditions, accelerating strain development and process optimization.

Why Choose Us?

- Specialized Attention: Personalized, dedicated support tailored for smaller-scale and niche programs.

- Advanced Facilities: Cutting-edge infrastructure ensuring precision, reliability, and compliance.

- Comprehensive Services: Integrated end-to-end solutions from strain engineering to GMP production.

- Flexible and Adaptable: Modular, rapidly scalable facilities accommodating diverse project needs and quick turnaround times.